Implementing Lean Project Management in Your Organization: A Step-by-Step Approach

Businesses continuously seek methods to optimize operations and provide exceptional customer value. Traditional project management methodologies, often with rigid processes and extensive documentation, can impede progress and lead to inefficiencies. Lean Project Management gives an innovative alternative by concentrating on the core objective: delivering maximum value to the customer while systematically eliminating waste.

This approach builds a culture of continuous improvement, leading to expedited project delivery, improved quality, and increased customer satisfaction. Explore in this article the core principles of Lean Project Management, with practical strategies and tools for successful implementation within your organization.

What is Lean Project Management?

Lean Project Management is a methodology that comes from Lean Manufacturing principles. Its primary focus is on delivering the most value to the customer while eliminating waste.

Traditional project management methods often involve strict processes and extensive documentation, which can slow things down and create inefficiencies. In contrast, Lean Project Management focuses on efficient workflows and continuous improvement to provide value more effectively.

What makes Lean Project Management unique is removing any activity that doesn't contribute to customer value. This means identifying unnecessary steps in the process and cutting them out, leading to faster project completion, improved quality, and better use of resources. This approach not only enhances efficiency but also promotes a culture of ongoing improvement, where your team always looks for ways to get better and more efficient.

Lean Project Management vs Agile

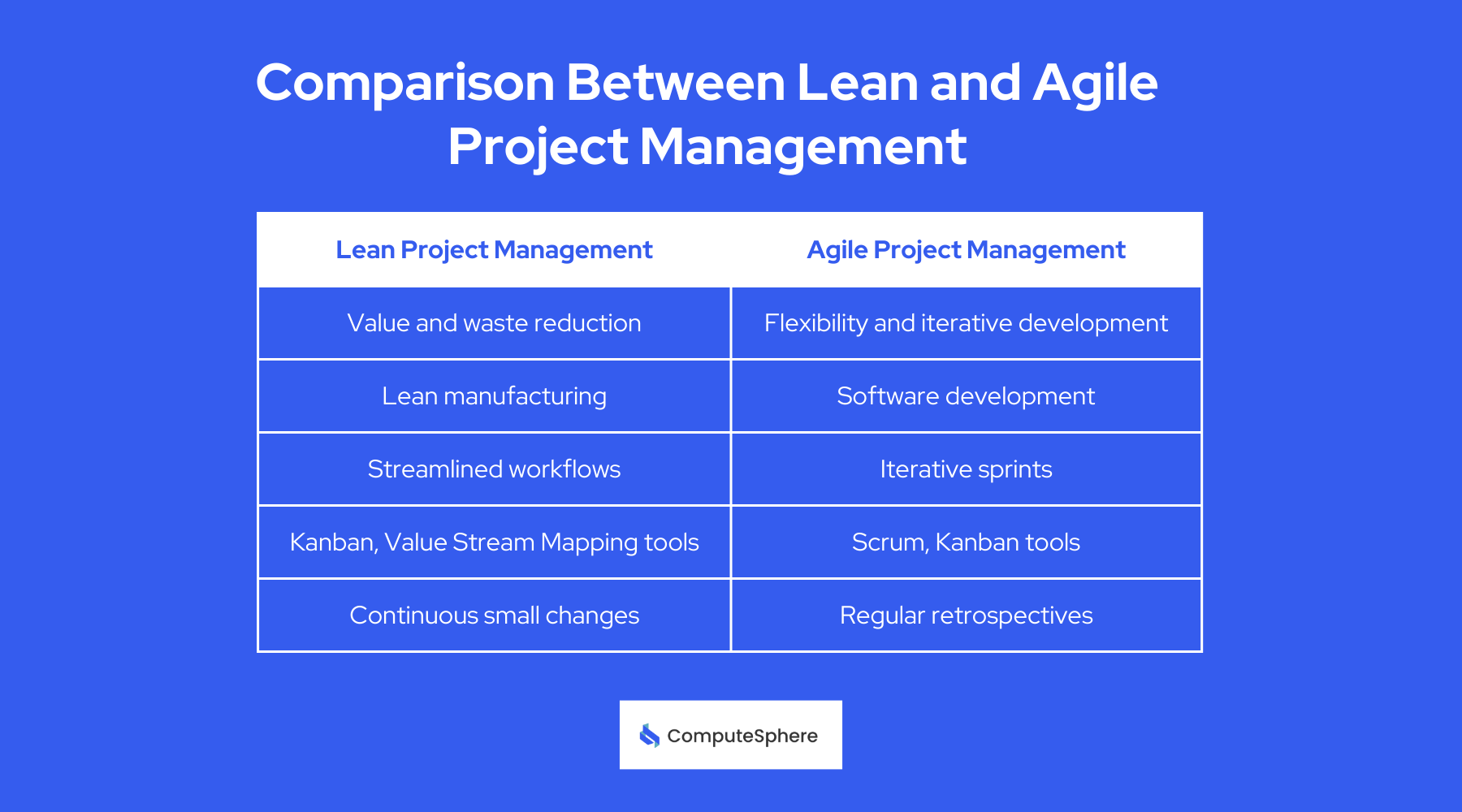

Lean and Agile are both popular project management methodologies, but they have distinct differences. Lean focuses on eliminating waste and delivering value through efficient workflows, while Agile emphasizes flexibility, collaboration, and iterative development.

Lean is ideal for projects where efficiency and waste reduction are important, such as manufacturing or service delivery. Agile is better suited for projects that require rapid adaptation and iterative development, such as software development.

Principles of Lean Project Management

Value: Focusing on What Truly Matters to the Customer

The first principle of Lean Project Management is defining what value means from the customer's perspective. This involves identifying what the customer needs and ensuring every action in the project contributes to providing that value. Concentrating on customer-defined value, you can align your team's efforts toward meaningful outcomes, Improving customer satisfaction and loyalty.

Value Stream: Identifying and Mapping Out All Steps in the Process

Mapping the value stream involves analyzing all steps involved in delivering a project. This helps identify and eliminate waste, ensuring that only value-adding activities remain. By creating a visual representation of the workflow, you can better pinpoint inefficiencies and streamline processes to improve overall productivity.

Flow: Ensuring a Smooth Process Flow Without Interruptions

Creating flow means organizing your processes so that work moves smoothly from one step to the next without delays. This requires removing bottlenecks and ensuring resources are available when needed. Achieving a smooth flow reduces waiting times and improves the efficiency of the entire project, leading to faster delivery and better resource utilization.

Pull: Producing Based on Demand to Avoid Overproduction

The pull principle focuses on producing work based on actual demand rather than forecasts. This helps you avoid overproduction and ensures resources are used efficiently. Responding to real-time customer needs, you can reduce inventory costs, minimize waste, and ensure that your efforts are always aligned with market demand.

Perfection: Continuously Improving Processes

Lean Project Management is a journey toward perfection. This principle involves regularly reviewing processes, seeking feedback, and making improvements to improve efficiency and value delivery continuously. This involves developing a culture of continuous improvement to adapt to changing conditions and innovations.

Steps to Implementing Lean Project Management

1. Identify Value

Understanding your customer's needs is the foundation of Lean Project Management. Start by engaging with customers to define what value means to them. This helps ensure that your efforts align with delivering what the customer truly wants. Use surveys, interviews, and feedback mechanisms to gather insights into customer expectations and preferences.

2. Map the Value Stream

Next, analyze your current workflows to identify all steps involved in delivering a project. Mapping the value stream helps visualize where waste occurs and provides insights into areas for improvement. Document each step, evaluate its contribution to value delivery, and identify non-value-adding activities that can be eliminated or optimized.

3. Create Flow

Streamline processes to ensure a smooth flow of work. This involves removing bottlenecks, ensuring resources are available when needed, and organizing tasks to move seamlessly from one stage to the next. Implement visual management tools like Kanban boards to track progress and maintain a continuous flow of work.

4. Establish Pull

Implement a pull system where work is produced based on actual demand. This avoids overproduction, reduces inventory costs, and ensures that resources are used efficiently. Use just-in-time principles to align production schedules with customer orders, minimizing waste and enhancing responsiveness to market changes.

5. Pursue Perfection

Finally, cultivate a culture of continuous improvement. Regularly review processes, seek feedback from team members and customers and make incremental changes to enhance efficiency and value delivery. Encourage a mindset of innovation and adaptability, where every team member is empowered to identify and implement improvements.

Lean Project Management Strategies

Best Practices for Lean Project Planning and Execution

Implementing Lean Project Management requires careful planning and execution. You can start by setting clear objectives and aligning your team around common goals. Encourage collaboration and open communication to ensure everyone is on the same page. Use visual management tools, such as Kanban boards, to track progress and identify bottlenecks.

Role of Leadership in Fostering a Lean Culture

Leadership plays an important role in building a Lean culture. Leaders must model Lean principles, provide support and resources, and create an environment that encourages experimentation and learning. Showing a commitment to Lean, you can inspire your team to continuous improvement.

Importance of Team Collaboration and Communication

Effective collaboration and communication within the team is essential for successful Lean Project Management. Encourage your team members to share ideas, provide feedback, and work together to solve problems.

Best Lean Project Management Tools

Lean project management tools come in various options to suit different budgets and needs. Some are available as offline apps for computers or mobile devices, while others can be accessed online through web browsers. For those frequently on the move, these tools are also compatible with smart devices. Here are some of the top Lean project management tools to consider:

Pivotal Tracker

Pivotal Tracker is designed to improve team collaboration by focusing on "user stories," which represent tasks. Teams can create epics, break them down into smaller stories, and assign them to sprints or individual team members. Pivotal Tracker offers project analytics, third-party integrations, and compatibility with both iOS and Android.

Kanbanize

Kanbanize (Businessmap) uses Kanban boards to help teams track progress, deadlines, and timelines. Its time-tracking feature provides detailed insights for creating reports, which can improve future project management. Kanbanize is excellent for visualizing tasks and understanding the time required for each.

TargetProcess

TargetProcess assists teams in managing sprints and visualizing development processes. It includes bug tracking and uses a Kanban interface to identify bottlenecks and work on continuous improvement initiatives. TargetProcess is suitable for both small and large projects, offering comprehensive features for larger teams.

Conclusion

Implementing Lean Project Management can greatly improve the way your organization handles projects, driving efficiency, improving quality, and maximizing value for your customers. By adopting Lean principles, you can streamline processes, eliminate waste, and build a culture of continuous improvement. The key to success lies in careful planning, the right tools, and a committed leadership that models Lean values. Encourage your team to embrace a mindset of continuous improvement, and regularly review and refine your processes.

Contents

Built for Builders. Priced for Startups.

Tired of unpredictable cloud bills? ComputeSphere offers modular, fixed-cost cloud hosting that grows with your startup—no DevOps headaches, no surprises.

Get StartedShare this article

Browse Some Related Blogs

Relevant and related contents you can read